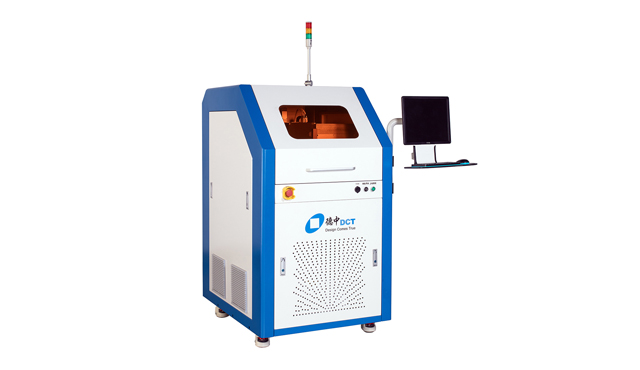

DirectLaser SA2 Small Format Laser Depaneling Equipment

High-precision, high-quality, the new standard for small-format equipment.

With the rapid advancement of electronic technology, designers are creating increasingly denser, smaller, thinner, and more irregular boards crating a challenging depaneling environment. DCT provides a more environmentally friendly, fast, precise and reliable solution to meet the needs of this trend.

Stress less

With laser cutting even if the components are very close to the cutting path, no stress is imparted to nearby components.

Accurate control of thermal effects

According to the thermal requirements lasers are selected to match the laser processing parameters to minimize the thermal impact.

Clean processing

Exhaust of gases and laser ablation byproducts is performed in real time during processing to minimize the impact of contamination on components.

Features

Directly data driven

High level automation

Break through mechanical limits

Contact free processing

Precise laser control

Product parameters

Technical data | DirectLaser SA2 |

| Working area | 350mm x 300mm |

Platform | Granite table and linear motor |

X/Y/Z resolution | ±2μm |

Reapetative accuracy | ±2μm |

Data processing software | CircuitCAM 7 Standard |

Machine software | DreamCreaTor 3 |

Automatic feed | Optional |

Camera postitioning | Optional |

Exhaust unit | Optional |

Dimension(W x H x D) | 890mm x 1,630mm x 1,150mm |

Weight | Approx. 600kg |

Power requirements | 380VAC/50Hz,2.4kW |

Ambient temperature | 22℃±2℃ |